by

admin essence

| Jan 16, 2024

Ceramaret is the only company in Europe that can produce alumina and zirconia components using inkjet printing.

Freedom of design – just one of the many advantages of additive manufacturing

|

|

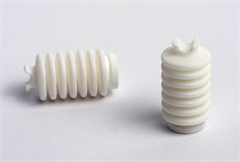

Among all the advantages of additive manufacturing, freedom of design is undoubtedly the most striking, and rightly so. 3D manufacturing makes it possible to create ceramic pieces with complex shapes and geometries that are otherwise difficult or impossible to achieve using traditional manufacturing methods. This opens the door to innovative designs optimised for specific performance criteria. More specifically, this often means eliminating the need for complex assembly by manufacturing complex one-piece structures.

While this is one of the most obvious advantages, it is by no means the only one. Additive manufacturing, including 3D printing of ceramics, can minimise material waste, as it adds the material layer by layer, thus reducing waste of raw materials. This also has an impact on the price of manufactured products.

Talking of price, 3D manufacturing processes can often reduce production costs by eliminating the need to produce costly and consumable moulds or tools. This also has a major impact on lead times, since it is possible to get straight to work on the product without having to wait for tools to be manufactured and delivered.

The responsiveness of the process offers unique flexibility for the manufacture of low volume components with a high design mix. At a more extreme level, we can also consider on-demand manufacturing if storage costs and the risks associated with stock management are critical.

In short, 3D manufacturing in the field of technical ceramics has significant advantages in terms of flexibility, customisation, cost reduction and design possibilities, making it an increasingly valuable technology for many industries.

Ceramaret's additive manufacturing technologies and materials

|

|

3D manufacturing of technical ceramics is a constantly evolving field, with several technologies and processes making it possible to create high-precision ceramic components. Each method and technique has its advantages and disadvantages, and may be broadly suitable for different applications. As is often the case, there is no single solution that works for all markets, applications, materials, etc.

At Ceramaret, we have decided to concentrate on inkjet technology. This technique uses printers to deposit liquid droplets containing ceramic nanoparticles on a surface, layer by layer. After each deposit, the material is cured by heating or a chemical process, before a new layer is added. This method is particularly advantageous as it requires very few post-printing operations. Once the build plate has been printed, the parts are immersed in water to dissolve the support material. After this stage, the parts are dried. Debinding can now begin. This is a critical stage for ceramic components, as it consists of eliminating the organic part that is still between the ceramic nanoparticles. One of the advantages of inkjet technology is that the amount of organic material in the printed parts is very low and comparable to pressed products, making the debinding step quick and easy. The work surface on inkjet printing machines makes them a real production tool capable of producing several thousand components a year, in a robust and industrial way.

Ceramaret is also able to produce components using DLP (Digital Light Processing) printing. This process consists of polymerising a viscous suspension of photosensitive liquid loaded with ceramic particles by projecting a mask of each cross-section of the said component.

The main advantages of this process are the surface quality after sintering and the flexibility in the development of new materials.

Exceptional value proposition of additive manufacturing

At Ceramaret, we want to focus primarily on design complexity, particularly with small-diameter structures and internal channels, as well as rapid prototyping on certain occasions. We are therefore able to meet our customers' needs for ZrO2 and Al2O3 materials and ATZ and ZTA composites. Other materials are being prepared or are in the development phase, notably DLP silicon nitride.

Two inkjet machines are available to our customers, with a 500 mm x 140 mm manufacturing build plate and standard component accuracy of 50 microns. The rough surface condition after sintering is 1.6 microns, with the ability to produce internal details down to 200 microns, such as a channel diameter. One machine is dedicated to alumina, the other to zirconia.

The DLP machine can produce ZTA and alumina components to commercial quality. The work surface for DLP technology is 102 mm x 64 mm with a height of 400 mm.

Additive manufacturing enhanced by our rework machining capabilities

|

|

The dimensional and geometric accuracy achieved by additive manufacturing of technical ceramics can vary depending on a number of factors, including the specific process, the materials used and the quality of the equipment. In addition to dimensional accuracy, the surface condition is defined by the process and the material used. For our applications, specifications can vary from surface condition, dimensional accuracy, mechanical strength, porosity, colour, etc. As with our powder-pressed parts, printed parts can be reworked to achieve, for example, a specific surface condition or dimensional tolerance that cannot be achieved by simple shaping.

Ceramaret boasts an extensive fleet of machines and capabilities that complement additive manufacturing, including processes such as polishing, flat surface finishing, CNC milling, centreless grinding, etc. This capability provides a unique dimension that enables us to achieve a high level of dimensional precision or specific surface condition according to need.

What is your project ?

Do you want to produce ceramic parts? Consult our specialists. Right from the design phase and drawing on in-depth technical experience, we will help you to select the right material and to design robust, reliable and safe products with exceptional properties.

Contact us