by

admin essence

| Jul 20, 2021

Recommended by many dentists and preferred by patients, ceramic dental implants offer much better cytotoxicological, histological and biochemical properties than those made from titanium. To ensure the new technologies involved are used correctly and all the safety criteria are met, it is essential to choose an experienced partner. A world-renowned manufacturer of high-precision technical ceramic parts, Ceramaret offers you all the necessary guarantees in terms of quality and reliability. Are you interested in marketing your own ceramic dental implants? Here are 4 great reasons to choose Ceramaret.

State-of-the-art materials

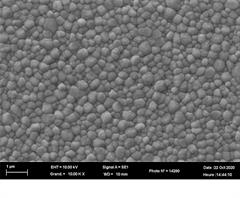

|

| Microstructure of the grain distribution of 3Y-TZP zirconia |

Compared to conventional titanium implants, ceramic implants offer a non-metallic and biocompatible alternative particularly appreciated by dental practitioners and their patients. Thanks to its favourable osteo-integration and its biocompatibility, a technical ceramic implant offers an ideal long-term alternative, particularly as concerns preventing the risks of rejection.

As a specialist in the production and machining of high-quality dental implants, Ceramaret can help you choose a ceramic material suited to your requirements. In general, two types of ceramic are used in the production of dental implants: zirconium oxide 3Y-TZP (ZrO2), and alumina toughened zirconium oxide (ATZ) which is a composite material composed of 80% zirconium oxide and 20% alumina. These two materials – which are hard, particularly resistant to wear and ageing, and highly biocompatible – stand out for their exceptional performance, linked to the expertly managed production processes. As a comparison, the flexural strength of the zirconium oxide developed at Ceramaret is up to 90% greater than the minimum values required by the ISO 13356 standard.

The composite material ATZ can deliver an even greater mechanical performance than zirconium oxide. This offers many freedoms in construction, while preserving the fatigue strength according to the ISO 14801 standard, which encompasses both the strength of the material and the product design. Finally, the particularly attractive opaque white colour of the ceramic blends seamlessly into the natural dentition.

Ceramaret supports you with innovative manufacturing technologies

|

| 2-piece dental implant made of zirconia fully manufactured by injection |

Working closely with its customers, Ceramaret adapts its manufacturing processes to your value chain, to the life cycle of your products and to your commercial needs. You design the implants; Ceramaret takes charge of selecting the most appropriate material and process, according to the regulatory requirements and your projected volumes, while optimising costs.

For production volumes up to 1000 parts per annum, Ceramaret often uses the raw machining/green machining method. This consists of machining the implant from pressed but not sintered ceramic. This method requires a very modest initial investment and offers valuable flexibility in the product development phase.

For medium production runs of 1000 to 5000 parts per annum, Ceramaret has developed a Ceramic injection moulding (CIM) process combined with hard part machining. This choice offers savings in terms of machining costs, as the ceramic blank is firstly injected in a mould adapted to several references, then sintered before finally being machined according to the final design. With this hybrid option, you benefit from the advantages of the injection process and significantly lower tooling costs.

Finally, for larger production volumes, injection moulding is the preferred process. All the (internal and external) properties of the implant will be defined in a mould and it will be produced in a single operation – requiring only a few finishing touches after the sintering operation.

Ceramaret quality

|

| Zirconia abutment manufactured by hard machining |

Ceramaret is a partner with extensive technical and regulatory experience to apply to the design and production of your ceramic implants.

With our support from the product design phase, you will benefit from a robust quality system throughout the manufacturing and validation process, from feasibility tests to innovative production solutions. Our Industrialisation and Quality departments will help you create the technical and regulatory documents, for the entire life cycle of your product.

The quality of the services offered by Ceramaret is structured by an integrated management system certified to ISO 9001, ISO 13485, ISO 14001 and ISO 45001 standards. This aspect is an integral part of our corporate strategy at Ceramaret and is part of our commitment to fully satisfy the requirements of our customers.

Ceramaret: extensive experience in the medical and dental sectors

|

| The internal part of the 2-piece 3Y-TZP zirconia dental implant fully injected |

Founded in 1907 in the heart of the Swiss watchmaking valley, Ceramaret is now one of the most highly respected manufacturers of components made from technical ceramics (zirconium oxide, alumina, silicon nitrides and silicon carbides). Components produced by Ceramaret have become internationally recognised for their quality and unmatched performance.

By choosing Ceramaret, you will benefit from our many decades of experience in moulding and machining technical ceramics and hard materials, particularly in the dental and medical sectors. It is this expertise which enables Ceramaret to offer you smart, sensible, and innovative solutions, expertise which is key to meeting all your technical requirements within the clearly defined framework of your budget and your safety standards.

What is your project?

Are you interested in producing implants or abutments in ceramic? We are here to help you. Contact our specialists for advice. Involved from the design phase and leveraging our extensive technical experience, we will help you choose the right material and design implants which are robust, reliable, safe and of the highest quality.

Contact us