by

admin essence

| Aug 24, 2022

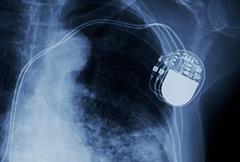

Over the last decade, the technological progression of implantable medical devices has been extraordinary. Implantable electrical devices such as pacemakers [1], cardiovascular defibrillators [2], implantable multichannel neuromuscular stimulators [3] and cochlear implants [4] have become widely accepted and used.

Why have ceramics gained importance within the medical devices market?

|

| Typical implanted neuro-simulator device |

Engineers have developed truly innovative solutions in order to increase the lifespan of these devices as well as to miniaturize them, thereby improving patient comfort. Increasing the number of electrical channels has also allowed the introduction of more complex wireless/IoT technologies [5].

Such sophisticated technological demands present numerous challenges for the development of new materials. One of the key factors in increasing the lifespan of an implantable device is its hermeticity, which depends on the hermetic reliability of the packaging material. Hence, hermetic packaging is essential to protect sensitive electronic components from external contamination. Various materials have been used in the packaging of medical devices, such as polymers, glasses, metals, and ceramics [5], each having advantages and drawbacks.

Polymers, which are easily mouldable and inexpensive, do not provide an impermeable barrier because of high moisture/gas permeability. Over time moisture seeps in and compromises the sensitive electronics.

Biocompatible metals such as titanium are the industry standard for hermetic packaging materials of implantable medical devices, but they also have certain limitations. Metal-only housing does not allow wireless power transfer without heating up the packaging. Therefore, more complex designs are needed, where the coil or antenna are placed outside the package to reduce significant loss of power or radio frequency signals.

Alternatively, bioceramics such as Al2O3 and ZrO2 (often stabilized tetragonal zirconia TZP) and bio glass are transparent to radio waves, affording them a key advantage over metallic materials. Ceramics or glass have also been largely used to produce insulated feedthroughs which provide electrical insolation of the package and avoid contact between the electrical wires and the metal case. One advantage of ceramics over bioactive glasses is their higher fracture toughness, which however remains lower than the one of metals [5].

Advances in the study and use of bio ceramic materials

|

| Ceramic case for Neurostimulator |

As for many medical applications (e.g., hip implants, dental implants, cochlear implants etc.), the early use of ceramic materials as components in medical devices resulted in some catastrophic failures. However, over the last decade ceramic engineering in the field of implantology has significantly improved the characteristics of the material. Experts have closely studied the relationship between the ceramic microstructure and its properties, engineering it to offer the best performance, even in challenging conditions such as those imposed by the human body.

Due to their intrinsic chemical stability/resistivity and to their proven biocompatibility, alumina, zirconia and combinations of them (composites), are nowadays largely employed for medical applications.

In the case of implantable medical devices, ceramics are preferred for their transparency to radio frequency windows (differently than titanium housing) which allows wireless transmission and communication between the implanted device and the exterior, as well as wireless recharging or monitoring of the device [6]. The elimination of percutaneous wires drastically reduces the risk of infection, thereby improving the patient’s quality of life.

Finally, a better understanding of the influence of different manufacturing technologies on the final ceramic properties makes the production of much more complex designs possible, ultimately leading to more sophisticated, precise ceramic components..

Selection of materials: Alumina & Zirconia

Alumina was one of the first ceramics used in implantology and is still widely used today - for instance for feedthroughs, where its high insulation properties are highly valued [6].

3Y-TZP Zirconia (3 mole% yttria doped – tetragonal stabilized zirconia) has a much higher flexural strength and fracture resistance than Alumina; therefore, it is preferred for long-term, load sensible applications such as cochlear implants or neuromuscular microstimulators. One drawback of 3Y-TZP is its low-temperature degradation (LTD) in moist environments and moderate to high temperatures [7]. It is well documented in literature that when exposed to water and heat, the metastable zirconia will undergo a crystalline transformation from tetragonal to monoclinic, which is accompanied by volume expansion, leading to micro-macro crack formations and a subsequent decrease in mechanical resistance.

Over the years, scientists have significantly improved the resistance of 3Y-TZP to LTD by improving both its microstructure and the manufacturing processes [8]. Moreover, composites such as alumina-toughened zirconia (ATZ), zirconia toughened alumina (ZTA) and zirconia doped with other oxides have shown higher hydrothermal stability, becoming reliable alternatives for long-term implantable devices.

The use of many of these ceramics for medical applications is standardized by ISO standards, e.g., ISO-6474 for Alumina and ISO-13356 for 3Y-TZP. The ISO standards have been written specifically to guide manufacturers in achieving the highest production quality standards to reduce the failure rate of ceramic components once implanted in the human body. While different medical sectors are often looking to achieve these same standards, it is important to note that the standards have been developed specifically for high load-bearing, demanding applications, such as hip prostheses.

Ceramaret engineers guide their customers in the understanding of industry requirements and support them in the development of the safest possible products for patients.

The importance of metal brazing and metal-to-ceramic hermetic sealing

|

| Small ceramic case |

One of the keys to the production of a hermetically sealed medical implantable device is to join the main metallic body (usually titanium alloy) and the ceramic components, such as the feedthrough or ceramic cases. Brazing two materials with such different CTEs (coefficient of thermal expansion) poses significant challenges and specific brazing solutions have had to be developed [6].

Moreover, the brazing itself needs to be biocompatible and thus requires the use of non-cytotoxic materials. Through the years, Ceramaret has worked with different players in the medical device supply chain, from legal manufacturers with the capability of integrating different production steps internally, to brazing suppliers, who provide expertise in bonding ceramic to metal parts.

Brazing indeed remains a critical process, which means that committed partnerships with experts are needed to produce safe and reliable implantable medical devices.

Ceramaret’s strengths and capabilities

Thanks to its technical expertise, Ceramaret actively works with its customers to design high-precision ceramic parts and to help customers choose the best material based on the desired properties.

Involved in all stages of the project, from the design and development stages to production, Ceramaret offers technically innovative and competitive solutions. Drawing on its cutting-edge in-house technical capability and expertise, Ceramaret designs superior tools and supports you throughout the entire manufacturing process.

For several decades, Ceramaret has been a world leader in the design and polishing of components made from ultra-hard materials. From engineering to stock management, Ceramaret is recognized for its ability to offer complete, customized solutions. From machining early-stage prototypes to ceramic injection molding for mass production, we strive to meet your strictest requirements. Each individual part is manufactured with extreme precision and adapted for use in the most innovative applications.

The expertise of our staff and our state-of-the-art production plants and equipment offer significant benefits to our customers. Our ISO 9001:2015, ISO 14001:2105, ISO 45001:2018 and ISO 13485:2016 certifications, combined with our strict quality requirements are your guarantee of success.

References:

1. Forde M, R. P. (2006). Implantable cardiac pacemakers. Bronzino JD (ed) Medical Devices and System-The Biomed Eng handbook.

2. Duffin. Implantable defibrillator. Bronzino JD (ed) Medical Devices and System-The Biomed Eng handbook.

3. Strojnik P., P. P. (2006). Implantable stimulators for neuromuscular control . Bronzino JD (ed) Medical devices and system-The biomedical engineering handbook.

4. Hochmair I., N. P. (2006). MED-EL Cochlear Implants: State of the Art and a Glimpse Into the Future. Trends in Amplification , 201-220.

5. Jiang G., D. D. (2010). Technology advances and challenges in hermetic packaging for implantable medical devices. Biological and Medical Physics-Biomedical Engineering, 27.

6. Shen K., M. M. (2021). Ceramic packaging in neural implants. Journal of Neural Engineering.

7. R.H. Hannink, P. K. (2000). Transformation Toughening in Zirconia-Containing Ceramics. Journal of American Society , 461-487.

8. P.Khajavi, Y. X. (2020). Tetragonal phase stability maps of ceria-yttria co-doped zirconia: From powders to sintered ceramics. Ceramics International .

What is your project?

Do you want to produce ceramic parts? Ask our specialists for advice. Based on our extensive technical experience, we help you to choose the right material and to design robust, reliable and safe products with outstanding properties.

Contact us